The Role of Plastic Shredders and Crushers in Modern Recycling #

Plastic waste is a growing global concern, with discarded products often ending up as non-biodegradable trash. Addressing this challenge requires effective solutions for processing and recycling plastic materials. Plastic shredders and crushers are essential tools in this effort, enabling the transformation of bulky plastic waste into manageable, recyclable fractions.

Why Invest in Plastic Shredding Technology? #

Plastic shredding machines offer an eco-friendly approach to recycling by breaking down various types of plastics, including thermoplastics like PE, PP, PVC, PS, PU, and PET, as well as thermosets and elastomers. These machines are engineered with customizable rotor designs and specialized cutting tools, allowing them to efficiently process a wide range of plastic materials. The resulting smaller plastic pieces can then be granulated and reused, supporting closed-loop recycling and reducing the environmental impact of plastic products.

Shredders are particularly valuable for their ability to handle bulky waste, streamlining the size reduction process and facilitating remanufacturing. By integrating shredders into recycling operations, organizations can contribute to sustainable recovery and reprocessing, helping to mitigate plastic pollution.

Product Range: Shredders, Crushers, and Pulverizers #

ACERETECH offers a diverse selection of shredders and crushers, each designed to address specific recycling needs. Below is an overview of available models:

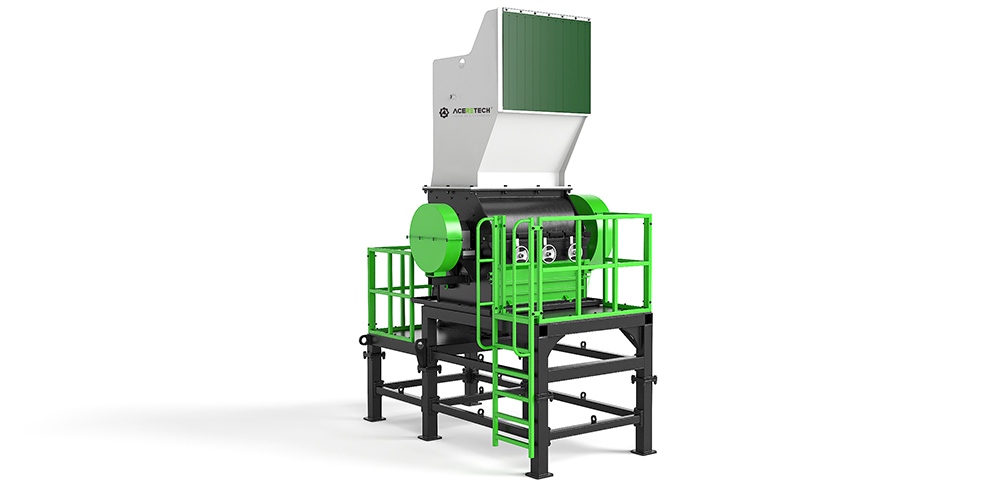

GE Plastic Recycling Shredder Machine For Waste Management

GE Plastic Recycling Shredder Machine For Waste Management

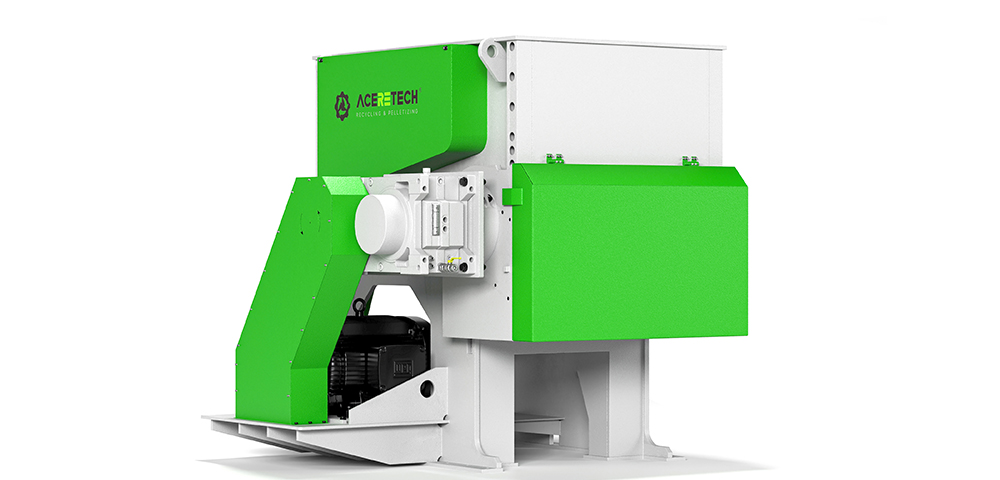

GF Series High Output Efficient Plastic Crusher Machine

GF Series High Output Efficient Plastic Crusher Machine

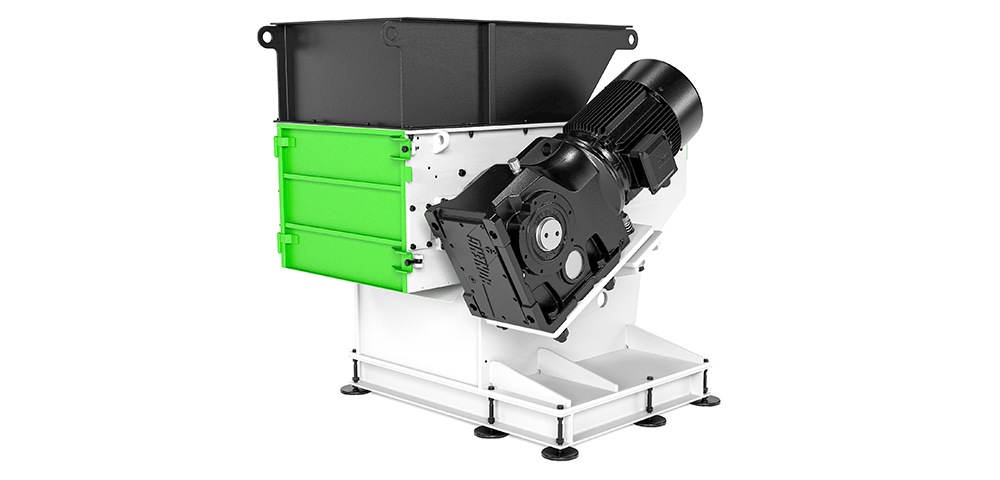

GH Heavy-Duty Plastic Crushers Grinding Machine

GH Heavy-Duty Plastic Crushers Grinding Machine

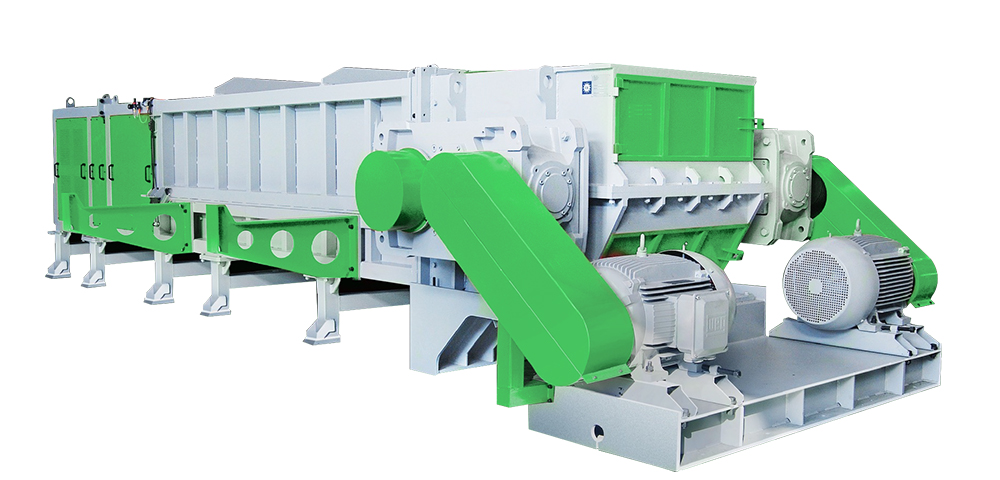

GP Series Plastic Crusher Machine For Grinding Long Plastic Pipes

GP Series Plastic Crusher Machine For Grinding Long Plastic Pipes

HS Series Single Shaft Hard Plastic Shredder

HS Series Single Shaft Hard Plastic Shredder

LS Series Plastic Waste Single Shaft Shredder With Small Volume And Wall Thickness

LS Series Plastic Waste Single Shaft Shredder With Small Volume And Wall Thickness

MS Series Adjustable PP PVC PE HDPE Pipe Waste Industail Plastic Shredder

MS Series Adjustable PP PVC PE HDPE Pipe Waste Industail Plastic Shredder

PS Series Single Shaft Plastic Shredder For Pipe Recycling

PS Series Single Shaft Plastic Shredder For Pipe Recycling

XS Series Heavy Single-Shaft Shredder

XS Series Heavy Single-Shaft Shredder

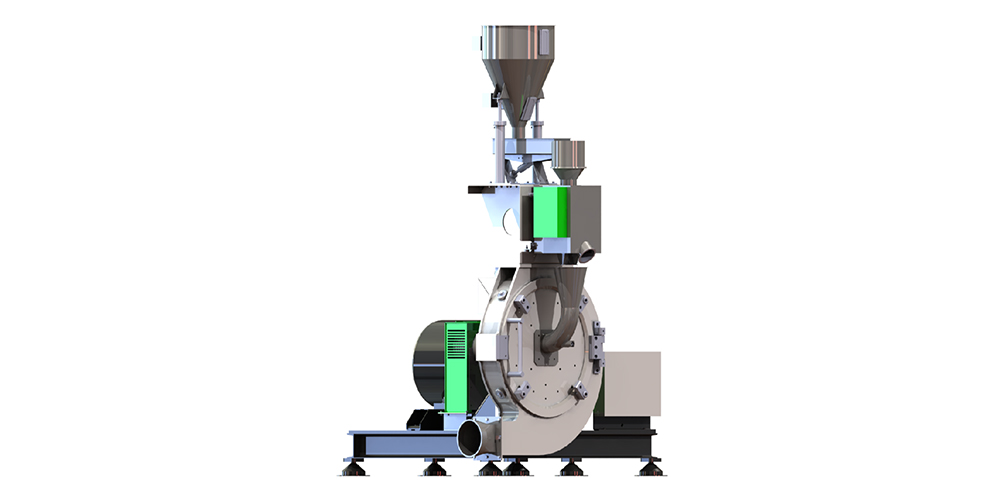

PM300 Plastic Recycling Pulverizer Machine with European Appliances

PM300 Plastic Recycling Pulverizer Machine with European Appliances

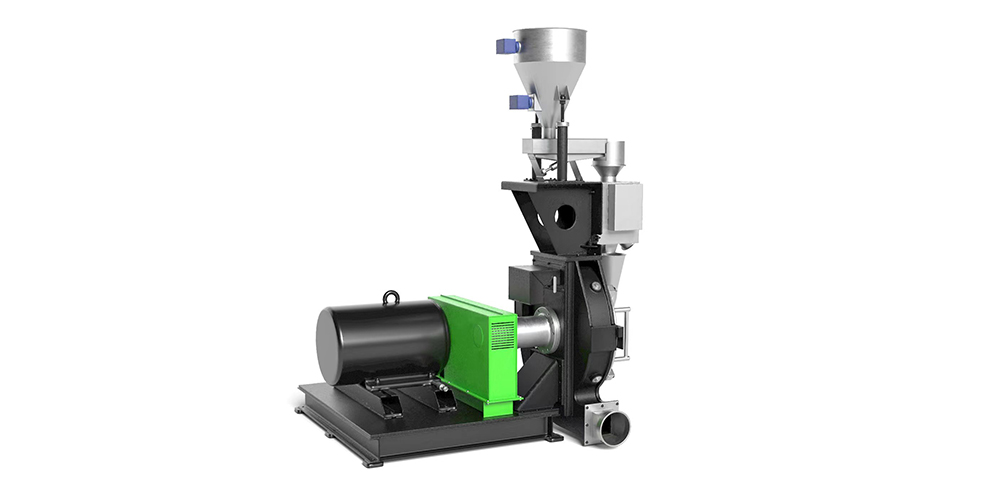

PM500 PVC Pulverizer Machine for Plastic Recycling

PM500 PVC Pulverizer Machine for Plastic Recycling

PM800 Carbon Steel Pulverizer Machine for Plastic Reuse

PM800 Carbon Steel Pulverizer Machine for Plastic Reuse

How Plastic Shredders Support Recycling Operations #

Plastic shredders, also known as crushers or granulators, are integral to recycling plants and production facilities. They break down plastic waste into smaller pieces, making it easier to process and reuse as raw materials or finished products in various industries. The machines are available in multiple models and configurations, tailored to the type and size of plastic waste being processed. Internal mechanisms can be designed for horizontal, vertical, or rotational movement, with adjustable speeds and torque to suit specific requirements.

Custom solutions are highly valued in the recycling industry, as they enable efficient size reduction and material recovery. Continuous innovation and engineering improvements help optimize recycling operations, ensuring economical and effective reprocessing of plastic waste.

Advantages of ACERETECH Shredders and Crushers #

ACERETECH specializes in engineering shredders and crushers that address the unique challenges of plastic recycling across diverse industries. Key features include:

- Heavy-duty construction for reliable operation in demanding environments

- Innovative designs that maximize shredding productivity and efficiency

- Flexible customization to handle various plastic types and volumes

- Intelligent engineering for straightforward operation and maintenance

These shredders are designed to reduce plastic waste to optimal sizes for post-processing, supporting a wide range of recycling applications. ACERETECH offers tailored solutions, from granulators to scrap shredders, to meet specific operational needs.

Considerations for Selecting a Shredder #

To ensure the best fit for your recycling requirements, consider the following:

- Types of waste materials to be processed

- Size of items to be fed into the shredder

- Required processing speed per hour

- Desired final product size after shredding

For more information or to discuss your specific needs, contact the ACERETECH team.

Locations #

7# Yuefeng road, Nanfeng town, Zhangjiagang city, Jiangsu province, China.

19# Dongsha Changfu Road, Nanfeng Town, Zhangjiagang City, Jiangsu Province, China.

B1705, Building A, Huijin Business Center, Yangshe Town, Zhangjiagang City, Jiangsu province, China.

Contact Information #

- Email: info@aceretech.com

- Phone: +86-512-58622021

- Fax: +86-512-58622021

For further details on products and solutions, visit the Products, Applications, Solutions, or About Us pages.